Centrifugal Pump

OBHT

HEAT TRANSFER OIL PUMP

APPLICATIONS AND USE

- For handling organic heat-transfer oils in heat-transfer plants. The fluids pumped must not contain any abrasive particles nor chemically attack the pump materials.

- Chemical and pharmaceutical industry:Heating of drying plats, stirring apparatuses, autoclaves, reaction tanks, in plants for the production of synthetic fibres, plastics,lacquer raw materials, in mixing and storage facilities for viscous media.

- Food industry:Heating of baking and roasting ovens, plants for the production of fatty acids, edible oils, glycerine, dry pastes.

- Textile, leather and paper industry:Heating of calenders, drying chambers, rolls, drying cylinders.

- Rubber and plastics industry:Heating of presses, automatic injection moulding machines,calenders, fusion kettles.

- Parint and lacquer industry:Heating of agitators and mixing vessels.

- Tar and bitumen-processing iindustry:Heating of storage tanks, tankers, for heating up heavy oil, in asphalt processing and roofing-felt production.

- Mineral-oil industry:Heating of transportation means, pipes and storage installations, for pre-heating of oils, in the bitumen production.

- Laundries:Heating of dryers, hot mangles, automatic ironing machines.

STRUCTURE AND FEATURE

- Simple maintainance with a horizontal centrifugal volute structure.

- Easy disassembly of component as it's a same disassembling way of general centrifugal pump.

- The pump has a long life span from a solidity of bearing housing.

- Use a good heat resistance and structure of material by adopting the maximum possible operation temperature to 350 degrees.

- Natural air-cooled cooling system has been adopted.

- Mounting m/seal the internal temperature is reduced to the function of bearing and m/seal are not a hindrance.

- Protect leakages with a function of stuffing box which is located in front of m/seal and installed a balance type of m/ seal when them/seal has broken.

- Axial load decreases according to a balance hole of impeller and the axis attached 2 bearings.

- It consists of a metal bearing from pump and a ball bearing from motor.

STANDARD SPECIFICATIONS

| Article | |

|---|---|

| Max, capacity range | 200㎥/HR |

| Max pump head | 80M |

| Max, temperature | 350℃ |

| Sealing method | M/SEAL |

| Flange standard | 10kg/㎠(RF, FF) |

| Impeller structure | CLOSE TYPE |

| Revolutions per minute | 1750rpm, 3500rpm |

| Flange position | Suction Flange(End Suction), Discharge Flange(Top Discharge) |

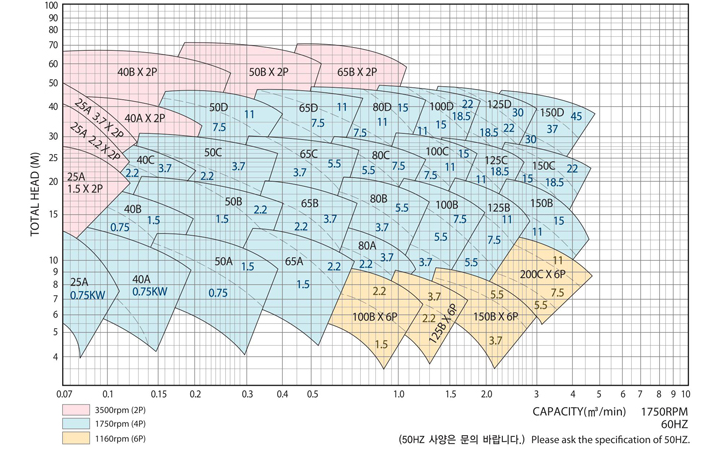

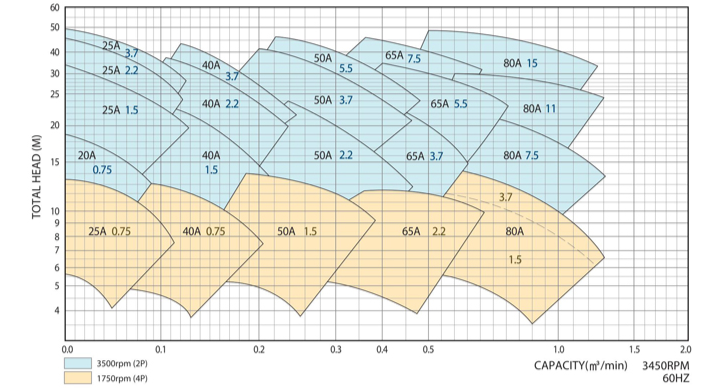

PERFORMANCE OVERVIEW

PERFORMANCE OVERVIEW

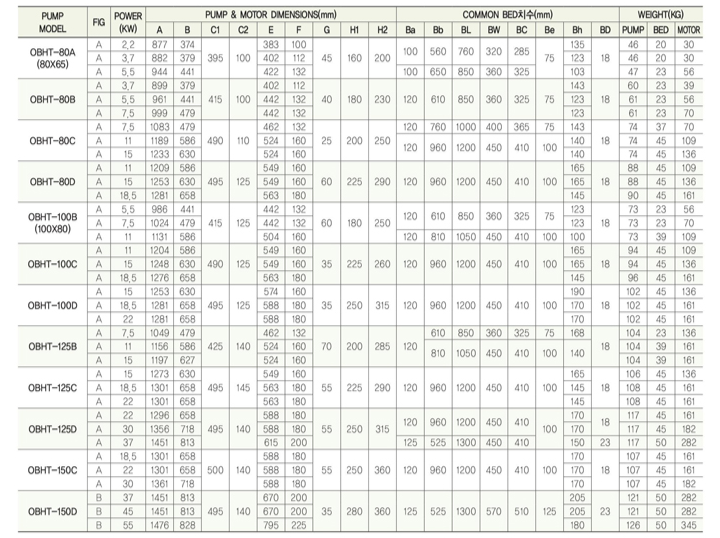

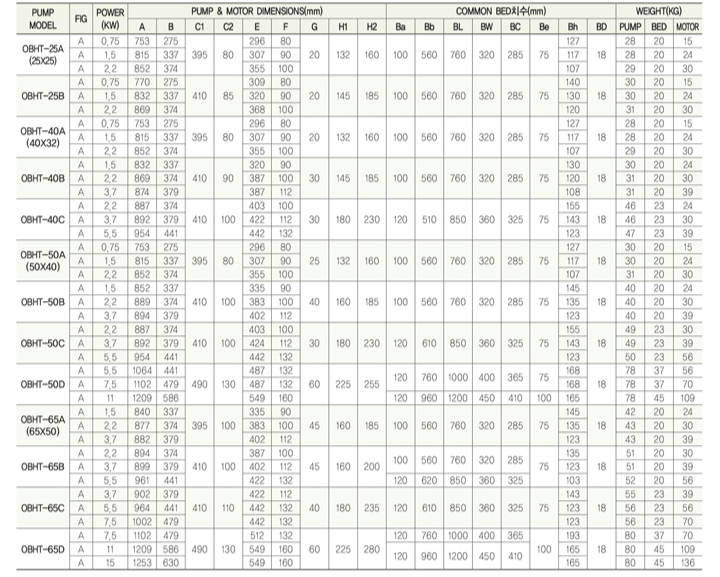

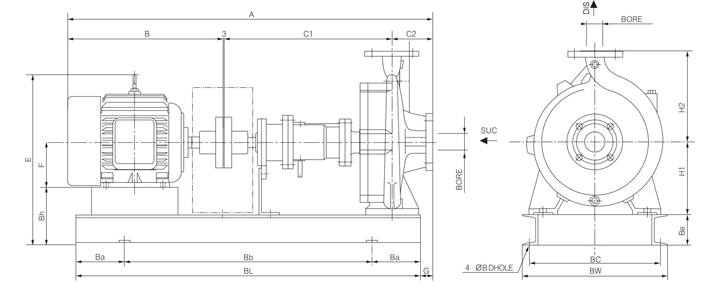

OUT LINE OF DIMENSION

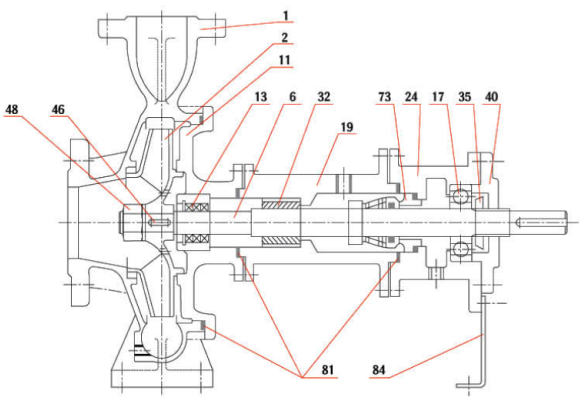

PUMP SECTIONAL VIEW

PUMP SECTIONAL VIEW

NAME OF PART

| No | NAME OF PART | Q'TY | MATERIAL |

|---|---|---|---|

| 1 | CASING | 1 | GOD450 |

| 2 | IMPELLER | 1 | GOD450 |

| 6 | SHAFT | 1 | SKD61 |

| 11 | STUFFING BOX | 1 | GOD450 |

| 13 | PACKIING | 3 | Graphite |

| 17 | BALL BEARING | 1 | STB2 |

| 19 | OIL BRACKET | 1 | GOD450 |

| 24 | BEARING HOUSING | 1 | GOD450 |

| 32 | METAL BEARING | 1 | Carbon |

| 35 | LOCK NUT | 1 | SM45C |

| 40 | BEARING COVER | 1 | GC200 |

| 46 | IMPELLER KEY | 1 | SM45C |

| 48 | IMPELLER NUT | 1 | High Tension |

| 73 | MECHANICAL SEAL | 1 | Solid Sic |

| 81 | GASKET | 1 | Graphite |

| 84 | SUPPORT | 1 | SS41 |

OUT LINE OF DIMENSION